Unbounded Post Tensioning System

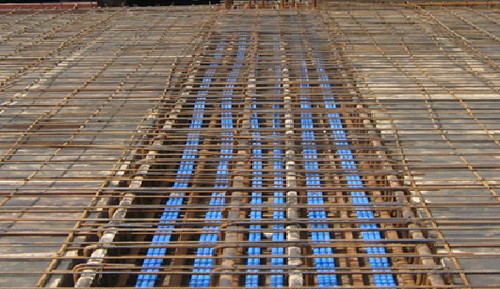

In this system, tendons which may be located inside the concrete are tensioned after the concrete has hardened. Internal tendons, which are contained within sheaths to prevent them from bonding to the concrete, can be arranged to follow the curvature of the structure and provide the most appropriate profile to suit the applied loading.

After the concrete has attained sufficient strength, the tendons are tensioned using jacks that bear upon the exposed face of cast-in anchorages at the ends of the tendons.

• Evolved from a grouted post-tensioning system before 1950, for building construction applications

• No need of grouting (grouting activity is eliminated)

• Saving of cost, time and material

• Installation made easier and flexible

• Each cable can be managed individually

• It can work efficiently in lesser depths where ducts cannot work capably

• Better elastic behavior, as far as earthquake events are concerned. Post-quake residual deformation is lesser.

Equipments & Materials

PRE-STRESSING STRAND ASTM A-416 SEVEN-WIRE LOW RELAXATION STRAND-270 KSI/KPSI

ADVANTAGES OF POST-TENSIONED

• Allows longer column spacing

• Reduces Structural Depth of members

• Results in larger floor to ceiling height

• Grater Deflection Control

• Reduces Structural Costs

• Un-cracked section at all times

ESSENTIAL ELEMENTS OF PT

• The cable or Tendon

• Fpu = 250 ksi, 270 ksi and 300 ksi(1 ksi = 6.89 Mpa)

• Seven wire strand

• Low relaxation

• The cable or tendon come in various diameters

• 3/8 Inch, 1/2 Inch, 0.6 Inch

This method is commonly used to create monolithic slabs for house construction in locations where expansive soils create problems for the typical perimeter foundation. All stresses from seasonal expansion and contraction of the underlying soil are taken into the entire tensioned slab, which supports the building without significant flexure.

Post-tensioning is also used in the construction of various bridges; both after concrete is cured after support by false work and by the assembly of prefabricated sections, as in the segmental bridge.

Among the advantages of this system are:

• Large reduction in traditional reinforcement requirements as tendons cannot destress in accidents

• Tendons can be easily “woven” allowing a more efficient design approach

• Higher ultimate strength due to bond generated between the strand and concrete