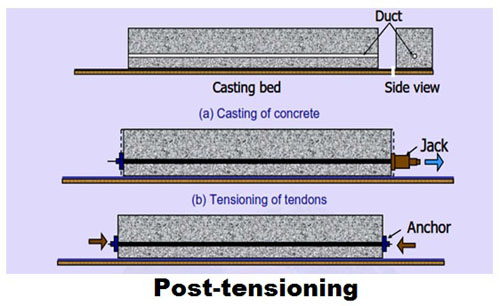

POST TENSION SYSTEMS

Post tensioned slab structures initially originated from Europe, whereas the advance research and development took place in USA and Australia. The first un-bonded post-tensioned slabs were erected in 1955 in United States of America. In the succeeding years, numerous post-tensioned slabs were designed and constructed in connection with the lift slab method. Post-tensioning enabled the lifting weight to be reduced, the deflection and cracking performance to be improved.

Post-tensioned construction has for many years occupied a very important position, especially in the construction of bridges and storage tanks. The reason for this lies in its decisive technical and economic advantages.

BENEFITS OF POST TENSIONING SYSTEMS

To fully appreciate the benefits of post-tensioning, it is important to understand the generic properties of concrete.Concrete is very strong in compression but weak in tension, i.e., it will crack when forces act to pull it apart. In a conventional concrete construction, if a load such as the cars in a parking garage is applied to a slab or beam, the beam will tend to deflect or sag. This deflection will cause the bottom of the beam to elongate slightly. Even a slight elongation is usually enough to cause cracking. Steel reinforcing bars (“rebar”) are typically embedded in the concrete as tensile reinforcement to limit the crack widths. Rebar is what is called “passive” reinforcement; however, it does not carry any force until the concrete has already deflected enough to crack. Post-tensioning tendons, on the other hand, are considered “active” reinforcing. Because it is pre-stressed, the steel is effective as reinforcement even though the concrete may not be cracked. Post-tensioned structures can be designed to have minimal deflection and cracking, even under a full load.